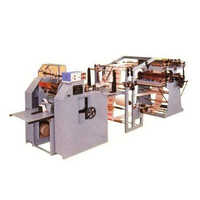

Bag Packaging Machines

(244 products)

Related Categories

Agarbatti Making Machines

Agricultural Machines & Tools

Bag Closing Machine

Bag Making Machine

Bag Packaging Machines

Banking Automation Products

Bending Machines

Billing Machine

Biscuit Making Machinery

Block Making Machine

Blow Moulding Machines

Box Making Machines

Braiding Machine

Brick Making Machine

Briquettes Making Machines

Briquetting Plants

CNC Machines

Cable Machinery

Carton Folding & Gluing Machines

Cashew Processing Machine

Cement Plant Machinery

Ceramic Machinery

Chapati Making Machines

Chemical Machinery

Chemical Processing Plants

Chuck

Coating Machine

Coil Winding Machines

Coir Machinery

Compression Testing Machines

Concrete Batching Plant

Confectionery Machinery

Construction Machinery

Cotton & Synthetic Spinners

Cutting Machine

Cylindrical Grinding Machinery

Dairy Equipment

Dairy Products Machinery

Decorative Laminate Machinery

Diamond Cutting Blades

Diamond Cutting Discs

Diamond Cutting Machines

Diamond Cutting Tools

Diamond Cutting Wheels

Diamond Grinding Wheel

Diamond Polishing Pads

Diamond Polishing Wheels

Dispenser Machine

Earth Moving Equipment & Machinery

Electrical Cable Machine

Embroidery Machine

Extraction Plants & Machinery

Extruder

Filter Machinery

Fishery Machinery

Flexo Printing Machinery

Flour Mill Machinery & Accessories

Food Processing Machinery

Footwear Machinery

Forest Machinery

Fruit & Vegetable Processing Machine

Gas Generation Equipment

Glass Processing Machines

Granite Processing Machinery

Grinding & Milling Machinery

Home Sewing Machine

Horticulture, Gardening & Irrigation Machinery

Hosiery Machinery

Ice Cream Machines

Ice Cream Plants

Industrial Gas Plants

Industrial Machinery & Parts

Injection Moulding Machine

Jewelry Making Tools & Machinery

Jute Mill Machinery

Knitting Machinery

Knitting Needles

Label & Sticker Labeling Machine

Lamination Machinery

Lamp Making Machinery

Laser Cutting Machines

Lathe Machine

Leather Machinery

Liquid Filling Machines

Machine Tools

Machine Tools Accessories

Machineries

Machinery & Parts

Marine Equipment

Metallic Processing Machinery

Metallurgy Lab Equipment

Mining, Exploration & Drilling Machinery

Mosaic Tiles Machinery

Oil & Gas Field Machinery & Equipment

Oil Expeller

Oil Extraction Machine

Oil Mill Machinery

Oil Refinery Plant

Other Machinery

Oxygen & Nitrogen Gas Plants

PU False Twister

Packaging Machine

Paint Manufacturing Machines

Paper Printing & Book Binding Machine

Paper, Paper Converting Machinery

Pharmaceutical Machinery

Planetary Mixer

Plant & Machinery

Plasma Cutting Machines

Plasma Welding Machines

Plastic Processing Machinery

Plywood Machinery

Polish & Polishing Material/Machinery

Polyurethane Foaming Machines

Pressure Fingers

Printing Ink Machinery

Printing Machinery

Processing Machines & Equipment

Pulverizers

Ribbon Blender

Rice Machinery

Rice Mill Machinery

Road Construction Machinery

Roll Forming Machinery

Rolling Mill Machinery

Rotogravure Printing Machine

Rotomoulding Machines

Rubber Extrusions

Rubber Machinery

Rubber Moulding Machines

Sealing Machine

Seed Processing Machinery

Sewing Machine

Sewing Machine Parts & Accessories

Shearing Machine

Shredding Machine

Shrink Wrapping Machines

Soap Making Machine

Soaps & Detergent Plants

Soda Making Machine

Sorting Machine

Special Purpose Machines

Spinning Machinery

Stamping Machine

Starch and Starch Machinery

Steel Rolling Mills Machinery

Strapping Machines

Stretch Wrapping Machines

Sugar Machinery

Tea & Coffee Machines

Textile & Garment Machinery

Textile Dyeing Machinery

Textile Finishing Machinery

Textile Machinery Spares, Components & Accessories

Textile Printing Machinery

Textile Processing Machinery

Tyres Repair & Retreading Machinery

Universal Testing Machines

Used Machinery

Vending Machine

Waste Tyre Recycling Plant

Water Jet Cutting Machine

Weaving Machinery

Weighbridge

Weighing Machines

Welding Electrode Plant & Machinery

Welding Machine

Wire Drawing Machines

Wire Machinery

Wire Winding Machines

Woodworking Machinery

Worsted Spinners

Explore More Categories

Mild Steel 300 Kg To 2000 Kg Jumbo Bag Packing Machine

Price: 468000 INR (Approx.)/Unit

MOQ- 1 Unit/Units

Control System - Frequency Speed Control

Material - Mild Steel

Voltage - 440 Volt (v)

14 Years

Sigma Instrumentation

Automatic Bag Filling System Power: 7 Horsepower (Hp)

Price: 3725000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Automatic Bag Filling System

Driven Type - Electric

Automatic Grade - Fully Automatic

14 Years

Business Type: Manufacturer | Supplier

SIGMA INSTRUMENTATION

Jumbo Bag Filling System Filling Capacity: 1 T/Hr

MOQ - 1 Unit/Units

Voltage - 440 Volt (v)

Machines Type - JUMBO BAG SYSTEM

Product Type - JUMBO BAG SYSTEM

11 Years

Business Type: Manufacturer | Exporter

ALTOMECH PRIVATE LTD.

Jumbo Bag Filling Machine

Price: 375000 INR (Approx.)/Set

MOQ - 1 Set/Sets

10 Years

Business Type: Manufacturer | Exporter

PRIYANSHI FABRICATORS & ENGINEERS

jumbo bag filling machine

Price: 450000.00 - 800000.00 INR (Approx.)/Set

MOQ - 1 set Set/Sets

Application - Beverage, Food, Other

7 Years

Business Type: Manufacturer

JAY INSTRUMENTS & SYSTEMS PRIVATE LIMITED

Automatic Jumbo Bag Packing Filling Machine

Price: 195000.00 - 450000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Packaging Material - Plastic

Driven Type - Pneumatic

Material - Stainless Steel

1 Years

Business Type: Manufacturer | Exporter

Elmec Technopac Machineries Private Limited

Automatic Bag Placer Machine

Price: 490000 INR (Approx.)/Unit

MOQ - 10 Unit/Units

Driven Type - Electric

Automatic Grade - Automatic

Material - Mild Steel

3 Years

Business Type: Manufacturer | Supplier

EDI ENTERPRISE PVT LTD

Jumbo Bagging System, Automation Grade: Semi-Automatic

Price: 50000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Electric Current Type - Electricity

Packaging Material - Milt Steel

Material - Mild Steel

4 Years

Business Type: Manufacturer

SHIVAM CONTROL SYSTEMS

Bag Filling

Price: 500000.00 INR (Approx.)/Unit

MOQ - 1 unit Unit/Units

8 Years

Business Type: Manufacturer | Exporter

R B TECHNOCRATS AND RECLAIMERS PVT. LTD.

Automatic Jumbo Bag Packing Filling Machine

Price: 195000.00 - 450000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Automatic Grade - Automatic

Driven Type - Pneumatic

Product Type - Jumbo Bag Packing Machine

4 Years

Business Type: Manufacturer | Supplier

SAVAN ENTERPRISE

Industrial Sand Bag Packing Machine

Price: 2500000.00 - 3500000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

4 Years

Business Type: Manufacturer | Distributor

THE SPARTAN MACHINERY

Fully Automatic Bagging System

MOQ - 1 Piece/Pieces

Product Type - Bagging System

Voltage - 220 Volt (v)

Control System - PLC

2 Years

Business Type: Manufacturer | Distributor

OPTIMA WEIGHTECH PRIVATE LIMITED

Semi Automatic / Automatic Jumbo Bag Filling Machines

MOQ - 5 Unit/Units

Material - Stainless Steel

Automatic Grade - Semi Automatic / Automatic

Driven Type - Electric

15 Years

Business Type: Manufacturer | Distributor

INDUS CONTROL & AUTOMATION PVT. LTD.

Automatic Jumbo Bag Packing Filling Machine

Price: 195000.00 - 450000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Packaging Material - Plastic

Material - Stainless Steel

Product Type - Jumbo Bag Packing Machine

Business Type: Manufacturer

Mahindra Plastic Industries

Matrix Formation Bagging Machine, Automation Grade: Automatic

Business Type: Manufacturer | Exporter

EMINENCE ENGINEERING

Pack Tech Bag Packaging Machines

Business Type: Manufacturer

Pack Tech Pack

Cement Bag Packing Machine

Business Type: Manufacturer | Exporter

SEPCON ENGINEERING (INDIA) PVT. LTD.

Three Phase 2 HP Semi Automatic Jumbo Bagging Machine

Price: 350000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Jumbo Bagging Machine

Material - Metal

Voltage - 415 Volt (v)

Business Type: Manufacturer

Samirika Industries

440Vac Semi Automatic Pop Powder Valve Type Bag Filling Machine Filling Capacity: 15 To 50 T/Hr

Price: 350000.00 - 650000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Production Capacity - 15 to 50 T/hr

Driven Type - Motorized or Pneumatically Operated

Filling Capacity - 15 to 50 T/hr

Business Type: Manufacturer | Service Provider

VINERAJ WEIGHING AUTOMATION

Indian Inquiries Only

Automatic Jumbo Bag Packing Filling Machine

Price: 195000.00 - 450000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Stainless Steel

Packaging Material - Plastic

Product Type - Jumbo Bag Packing Machine

Business Type: Manufacturer

FLS India Pvt. Ltd.

Automatic Jumbo Bag Packing Filling Machine

Price: 195000.00 - 450000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Stainless Steel

Packaging Material - Plastic

Driven Type - Pneumatic

Business Type: Manufacturer | Supplier

Sevy Techno Trend

Bagging System

Business Type: Manufacturer

Precia Molen India Ltd.

Semi Automatic Jumbo Bag Filling Machine With Capacity Of 700 Bags Per Hour Dimension(L*W*H): 1400X1400X5000Mm Millimeter (Mm)

Price: 1 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Power - 2 Horsepower (HP)

Automatic Grade - Semi Automatic

Dimension(L*W*H) - 1400x1400x5000mm Millimeter (mm)

Business Type: Manufacturer | Distributor

SHREE GURU ENTERPRISES INDIA

Green Pouch Making Machine

Business Type: Manufacturer | Supplier

PRIMO TECH PACK

Jumbo Bag Unloading System

MOQ - 1 Unit/Units

Load Capacity - 5 Tonne

Belt Conveyor - Other

Vertical Conveyor - Vertical Lift

Business Type: Manufacturer | Exporter

RAJ DEEP ENVIROCON LLP

Bag Packaging Machines Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Shree Chamunda Micro Industries | Ahmedabad, India | 16 Years |

| Indus Control & Automation Pvt. Ltd. | Bengaluru, India | 15 Years |

| Sigma Instrumentation | Ahmedabad, India | 14 Years |

| Altomech Private Ltd. | Coimbatore, India | 11 Years |

| Priyanshi Fabricators & Engineers | Ahmedabad, India | 10 Years |

| Anssen Metallurgy Group Co., Ltd. | Dalian, China | 9 Years |

| R B Technocrats And Reclaimers Pvt. Ltd. | Jaisinghpur, India | 8 Years |

| Jay Instruments & Systems Private Limited | Navi Mumbai, India | 7 Years |

| Touch And Glow | Nalasopara, India | 7 Years |

| Shivam Control Systems | Vadodara, India | 4 Years |

About: Bag Packaging Machines

Bag packaging machines are automated devices made for quickly and effectively putting items into bags or pouches. Industries like manufacturing, food, agriculture, and medicine all frequently employ this equipment. These devices simplify packaging by automating procedures like product filling, bag formation, labelling, and sealing.

The benefits of bag packaging machines include precise and consistent packing, quick production rates, lower labour costs, and greater product presentation and shelf life. They are capable of handling a wide variety of goods, including powders, solids, liquids, granules, and even objects with unusual shapes. These devices aid in boosting productivity and efficiency in packaging activities, resulting in dependable packaging for various items.

Different Categories of Bag Packaging Machines

Numerous bag packaging machines are available, each created to meet certain packaging needs. Let's examine some of the major divisions:

- Vertical Form-Fill-Seal (VFFS) Machines: Machines for vertical form-fill-seal (VFFS): These devices make bags from rolls of film, fill them with the product, and then seal them vertically. For packing dry commodities including coffee, snacks, powders, and grains, VFFS machines are frequently utilized.

- Horizontal Form-Fill-Seal (HFFS) Machines: Machines that use horizontal form-fill-seal technology, or HFFS, fill pre-made pouches or bags with product horizontally before sealing them. Products including candy, snacks, sauces, drinks, and personal care goods can all be packaged using these machines.

- Pre-Made Pouch Packaging Machines: These devices are used to fill and seal pre-formed pouches or bags. Pet treats, food, cosmetics, and household goods are just a few of the products that these machines can handle.

- Sachet Packaging Machines: Machines for making single-use sachets or packets for items like spices, sauces, medicines, and instant coffee are known as sachet packaging machines. They are designed to be practical and help with portion management.

- Bag-in-Box Packaging Devices: These devices load liquids or powders into flexible bags and then position those bags within a cardboard box. Industries like dairy, beverage, and bulk food packing use these devices.

- Vacuum packing equipment: Before sealing bags or pouches, vacuum packaging equipment removes air from the contents. They are perfect for increasing the shelf life of perishable foods and shielding delicate goods from oxidation, moisture, and spoiling.

Advantages of Using Bag Packaging Machines

Businesses in a variety of industries can benefit from using bag-packing machines in a number of ways. Among the key benefits are:

- Gains in Efficiency: Automating the packaging process with bag packaging machines improves productivity and efficiency. They can handle a huge number of goods fast, which lowers the need for labor and boosts overall output.

- Consistency and Accuracy: By carefully measuring and putting items into pouches or bags, these machines assure exact and consistent packing. Regulating portion sizes and ensuring that weight or volume standards are satisfied, aids in maintaining product quality.

- Versatility: Bag packing machines are capable of handling a wide range of goods, including liquids, powders, grains, granules, and even objects of unusual shapes. They permit due to their compatibility.

- Enhanced Product Protection: When pouches and bags are properly closed, the contents are guarded against irritants, UV rays, moisture, air, and airborne particles. This aids in preserving the product's quality, integrity, freshness, and shelf life.

- Better Presentation: Bag packaging machines offer professional packaging, increasing the products' visual appeal. Personalized branding and labeling on neatly wrapped bags or pouches lead to better marketability and a positive client experience.

- Cost savings: Over time, bag packaging machines could bring cost savings. They cut down on material waste in packaging, improve manufacturing efficiency, and reduce the need for manual labor, all of which increase profitability and lower operating costs.

Market Trends in Bag Packaging Machines

Various market trends are influencing this sector. Here are a few noticeable trends:

Automation and Industry 4.0 Integration: To increase production speed, maximise efficiency, and enable real-time monitoring and control, bag packaging machines are being integrated with cutting-edge technologies like artificial intelligence, robotics, and machine learning.

Environmentally conscious consumers are becoming more aware of the need for sustainable packaging solutions, which is driving up demand for these products. These devices are made to work with environmentally friendly materials, minimise packaging waste, and support recycling and biodegradability.

- Flexibility and Customization: There is an increasing demand on the market for bag packaging equipment that can work with a variety of bag sizes, shapes, and materials. In order to accommodate different products and packaging requirements, customization capabilities—such as flexible bagging settings and rapid changeovers—are becoming more and more crucial.

- Smart Packaging Features: Bag packaging machines are combining intelligent sensors, connection, and data collection capabilities as examples of smart packaging features. This makes it possible to check the quality, monitor packing procedures in real time, do preventive maintenance, and increase supply chain traceability.

- User-Friendly Interfaces and Controls: Manufacturers are putting a lot of effort into creating user-friendly interfaces and controls for machines that package bags. Operating, debugging, and maintaining a system is made simpler and more effective by user-friendly software, intuitive touchscreens, and remote access capabilities.

- Integration with Downstream Operations: Larger manufacturing lines and integrated packaging systems are including bag packaging equipment. With the seamless integration of extra equipment like labelers, fillers, and conveyors, operations may be made more efficient and streamlined.

- E-commerce is expanding packing: To efficiently handle the packing of online orders, there is a demand for bag packaging equipment as e-commerce grows. This features automatic labeling, automatic bagging, and customization for different products and package sizes.

- Regulations for the Food Industry: Equipment used to pack bags must go by strict guidelines for the food business. Manufacturers adhere to food safety requirements while choosing the materials and designs for hygienic packaging and preventing product contamination.

What Should One Consider When Choosing Bag Packaging Machines

There are several crucial considerations that should be taken into account while choosing bag-packing equipment for your company, including:

- Packaging prerequisites: Consider your specific packaging needs, taking into account elements like the nature of the products you are packaging, their physical characteristics, the chosen bag materials and sizes, and the required manufacturing capacity of the good.

- Machine Capacity and Speed: You must consider both the production capacity and speed of the bag packaging machine while selecting the equipment. Find out if the machine can run at the required speed without compromising the quality of the output while handling the stated output volume.

- Versatility and adaptability: Make sure the bag packaging machine can handle a variety of bag sizes, materials, and product types before you acquire it. You should also seek for equipment that is simple to alter and switch between different packing modes quickly and easily.

- Reliability and Durability: Determine the machine's endurance and look for models with a proven track record of performance and longevity.

- Automation and Integration: Evaluate the bag packing machine's level of automation and integration. Depending on your production needs, take into account features like programmable logic controllers (PLCs), touchscreen user interfaces, remote monitoring, and connectivity with other equipment in your production line.

- Friendliness and Operator Qualifications: Take into mind how user- and operator-friendly the machine is. It can improve output while shortening the learning curve for your workers.

- Cost and Return on Investment (ROI): Consider the machine's cost and potential ROI. Aspects like the initial investment, ongoing costs (such as energy use and maintenance), and the expected machine lifespan should all be taken into consideration.

- Safety and compliance: Verify that the device conforms with all applicable industry standards and safety laws. Conformity to hygiene and safety standards is crucial, especially in sectors like food and medicine.

FAQs: Bag Packaging Machines

Q. What are the advantages of using bag packaging machines?

Ans: Below are some of the key advantages of using bag packaging machine include:

- Enhances Efficiency

- Consistency and Accuracy

- Cost Savings

- Reduced Risk of Human Error

- Waste Reduction

- Regulatory Compliance

- Improved Workflow and Scalability

- Versatility

- Enhanced Product Protection

- Improved Presentation

Q. How often does a bag packaging machine require maintenance?

Ans: A bag packaging machine's maintenance needs may vary based on a number of factors, such as the model of the machine, its working environment, how frequently it is used, and the kinds of products it is used to package. Following the manufacturer's recommendations for maintenance schedules and intervals is generally advised.

Q. How much does a bag packaging machine cost?

Ans: Various factors, such as the machine's kind, features, specifications, capacity, and the manufacturer or supplier, can have a considerable impact on the price of a bag-packing machine. For rudimentary models, it can cost several hundred thousand rupees, while high-capacity or fully automated systems can cost several million rupees.

Q. What are the different types of bag packaging machines available?

Ans: There are several different types of bag packaging machines available as follows:

- Vertical Form-Fill-Seal (VFFS) Machines

- Horizontal Form-Fill-Seal (HFFS) Machines

- Pre-Made Pouch Packaging Machines

- Sachet Packaging Machines

- Bag-in-Box Machines

- Multihead Weighing Machines

- Automatic vs. Semi-Automatic Machines

Related Categories

Related Categories

Agarbatti Making Machines

Agricultural Machines & Tools

Bag Closing Machine

Bag Making Machine

Bag Packaging Machines

Banking Automation Products

Bending Machines

Billing Machine

Biscuit Making Machinery

Block Making Machine

Blow Moulding Machines

Box Making Machines

Braiding Machine

Brick Making Machine

Briquettes Making Machines

Briquetting Plants

CNC Machines

Cable Machinery

Carton Folding & Gluing Machines

Cashew Processing Machine

Cement Plant Machinery

Ceramic Machinery

Chapati Making Machines

Chemical Machinery

Chemical Processing Plants

Chuck

Coating Machine

Coil Winding Machines

Coir Machinery

Compression Testing Machines

Concrete Batching Plant

Confectionery Machinery

Construction Machinery

Cotton & Synthetic Spinners

Cutting Machine

Cylindrical Grinding Machinery

Dairy Equipment

Dairy Products Machinery

Decorative Laminate Machinery

Diamond Cutting Blades

Diamond Cutting Discs

Diamond Cutting Machines

Diamond Cutting Tools

Diamond Cutting Wheels

Diamond Grinding Wheel

Diamond Polishing Pads

Diamond Polishing Wheels

Dispenser Machine

Earth Moving Equipment & Machinery

Electrical Cable Machine

Embroidery Machine

Extraction Plants & Machinery

Extruder

Filter Machinery

Fishery Machinery

Flexo Printing Machinery

Flour Mill Machinery & Accessories

Food Processing Machinery

Footwear Machinery

Forest Machinery

Fruit & Vegetable Processing Machine

Gas Generation Equipment

Glass Processing Machines

Granite Processing Machinery

Grinding & Milling Machinery

Home Sewing Machine

Horticulture, Gardening & Irrigation Machinery

Hosiery Machinery

Ice Cream Machines

Ice Cream Plants

Industrial Gas Plants

Industrial Machinery & Parts

Injection Moulding Machine

Jewelry Making Tools & Machinery

Jute Mill Machinery

Knitting Machinery

Knitting Needles

Label & Sticker Labeling Machine

Lamination Machinery

Lamp Making Machinery

Laser Cutting Machines

Lathe Machine

Leather Machinery

Liquid Filling Machines

Machine Tools

Machine Tools Accessories

Machineries

Machinery & Parts

Marine Equipment

Metallic Processing Machinery

Metallurgy Lab Equipment

Mining, Exploration & Drilling Machinery

Mosaic Tiles Machinery

Oil & Gas Field Machinery & Equipment

Oil Expeller

Oil Extraction Machine

Oil Mill Machinery

Oil Refinery Plant

Other Machinery

Oxygen & Nitrogen Gas Plants

PU False Twister

Packaging Machine

Paint Manufacturing Machines

Paper Printing & Book Binding Machine

Paper, Paper Converting Machinery

Pharmaceutical Machinery

Planetary Mixer

Plant & Machinery

Plasma Cutting Machines

Plasma Welding Machines

Plastic Processing Machinery

Plywood Machinery

Polish & Polishing Material/Machinery

Polyurethane Foaming Machines

Pressure Fingers

Printing Ink Machinery

Printing Machinery

Processing Machines & Equipment

Pulverizers

Ribbon Blender

Rice Machinery

Rice Mill Machinery

Road Construction Machinery

Roll Forming Machinery

Rolling Mill Machinery

Rotogravure Printing Machine

Rotomoulding Machines

Rubber Extrusions

Rubber Machinery

Rubber Moulding Machines

Sealing Machine

Seed Processing Machinery

Sewing Machine

Sewing Machine Parts & Accessories

Shearing Machine

Shredding Machine

Shrink Wrapping Machines

Soap Making Machine

Soaps & Detergent Plants

Soda Making Machine

Sorting Machine

Special Purpose Machines

Spinning Machinery

Stamping Machine

Starch and Starch Machinery

Steel Rolling Mills Machinery

Strapping Machines

Stretch Wrapping Machines

Sugar Machinery

Tea & Coffee Machines

Textile & Garment Machinery

Textile Dyeing Machinery

Textile Finishing Machinery

Textile Machinery Spares, Components & Accessories

Textile Printing Machinery

Textile Processing Machinery

Tyres Repair & Retreading Machinery

Universal Testing Machines

Used Machinery

Vending Machine

Waste Tyre Recycling Plant

Water Jet Cutting Machine

Weaving Machinery

Weighbridge

Weighing Machines

Welding Electrode Plant & Machinery

Welding Machine

Wire Drawing Machines

Wire Machinery

Wire Winding Machines

Woodworking Machinery

Worsted Spinners